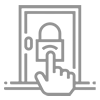

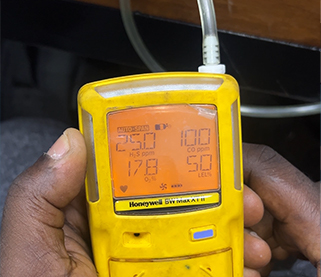

Imagine this: You are about to send your team into a deep tank or a pit. You lower your gas monitor. It beeps once, lights up green, and shows “0” on the screen.

You think, “tuko salama” (Okay, we are safe). You send the team in.

But what if the machine is lying?

We trust these yellow boxes with our lives. But there is a silent problem that affects every gas monitor in East Africa, from the mines in Tanzania to the factories in Nairobi. It is called Sensor Drift.

Here is the simple truth about what it is, why it happens, and how to stop it from hurting your people.

What is Sensor Drift?

In simple terms, Drift is when your gas detector gets “old eyes.”

Think of a new car. When you buy it, the speedometer is perfect. If you drive at 50 kph, it shows 50 kph. But imagine if, after two years, you are driving at 50 kph, but the dashboard only shows 30 kph. You are speeding, but the car tells you that you are slow.

This is Drift.

- The Truth: There is dangerous gas in the air.

- The Lie: The screen says “0” or a very low number.

The machine isn’t broken. The battery is fine. The screen works. But the “nose” inside the machine has lost its ability to smell the danger.

Why Does It Happen? (It’s Not Just You)

Gas detectors are not like radios or phones that work the same way for years. Inside the detector, there is a chemical sensor. It is like a living thing, it breathes the air.

In our environment, three main things make these sensors fail kidogo kidogo (little by little):

1. The Heat

Our region can be hot. Inside the sensor, there is a special liquid (like the acid in a car battery). When it gets very hot and dry, that liquid evaporates. As the liquid dries up, the sensor gets slow. It takes longer to “smell” the gas. A fresh sensor might take 10 seconds to alarm; a dried-out sensor might take 1 minute. In an emergency, 1 minute is too long.

2. The Poisons (Silicone)

This is very common in workshops. Do you use spray polish, lubricants, or strong cleaning soaps? Many of these contain Silicones.

If silicone vapours touch the sensor, they coat it like a layer of varnish or superglue. The sensor is now “blocked.” The gas cannot get in. The monitor will read “0” forever, even if the room is full of explosive gas.

3. The Dust

We work in dusty places. Dust can block the tiny filter on the front. If the air cannot get in, the sensor cannot read it.

The Most Dangerous Number: The “False Zero”

Here is the scary part.

If your sensor has drifted downwards (lost sensitivity), it might technically be reading -10 (negative ten). But the manufacturers don’t want to confuse you with negative numbers. So, the software is programmed to just show “0”.

Let’s do the math:

- Your sensor is weak. It starts at -10 (but the screen lies and says 0).

- You walk into a room with 10 ppm of poison gas.

- The sensor goes up by 10 points.

- -10 + 10 = 0.

The screen still says 0. You are breathing poison, but the machine is silent. This is why we call it the Silent Killer.

The Solution: Bump Test vs. Calibration

How do we fix this? You need to know the difference between “Checking the Oil” and “Full Service.”

1. The Bump Test (Every Morning)

This is like checking your oil before a long journey.

- What to do: Blast the monitor with a little bit of gas from a bottle.

- The Goal: Does the alarm scream? Do the lights flash?

- When: Do this every single day before work starts. If it doesn’t scream, do not use it.

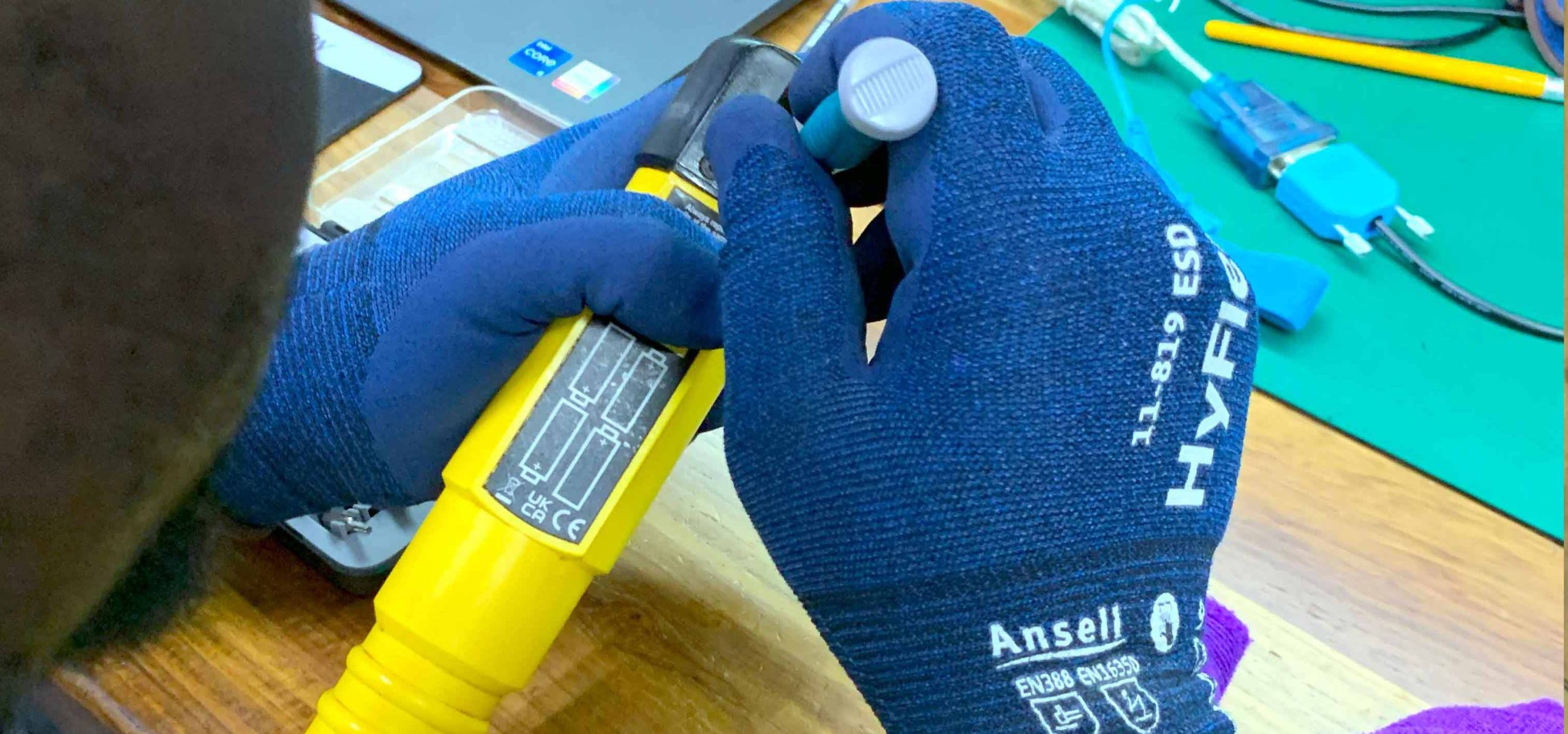

2. Calibration (Once in 6 Month)

This is like taking your car for a full service.

- What to do: The machine is connected to a gas cylinder for a few minutes. The computer inside adjusts the sensor. It fixes the drift. It resets the “Zero” back to the true Zero.

- When: Usually once in 6 month.

Final Word

Don’t treat your gas detector like a smoke alarm in your house that you ignore for 10 years. Treat it like fresh milk, it goes bad over time.

- Heat kills it.

- Chemicals block it.

- Time weakens it.

If you want to go home to your family safely, follow this rule: If you haven’t tested it with gas, do not trust the “Zero.”

Contact Us for Calibration Services:

To schedule your calibration or inquire about our services, contact us at:

Headquarters Plot No. 37, Bibi Titi Road Dar es Salaam, Tanzania

Branch Office Underneath Sabodo Carpark Shop 6, Unit 18, 598/73 India Street Dar es Salaam, Tanzania

Phone: +255 788 580 055 | +255 222 110 387 Email: info@sas.co.tz

Safety & Security Centre – Secure your tomorrow, today!